Discover our cutting-edge equipment designed to produce high-quality and safe health and hygiene products efficiently.

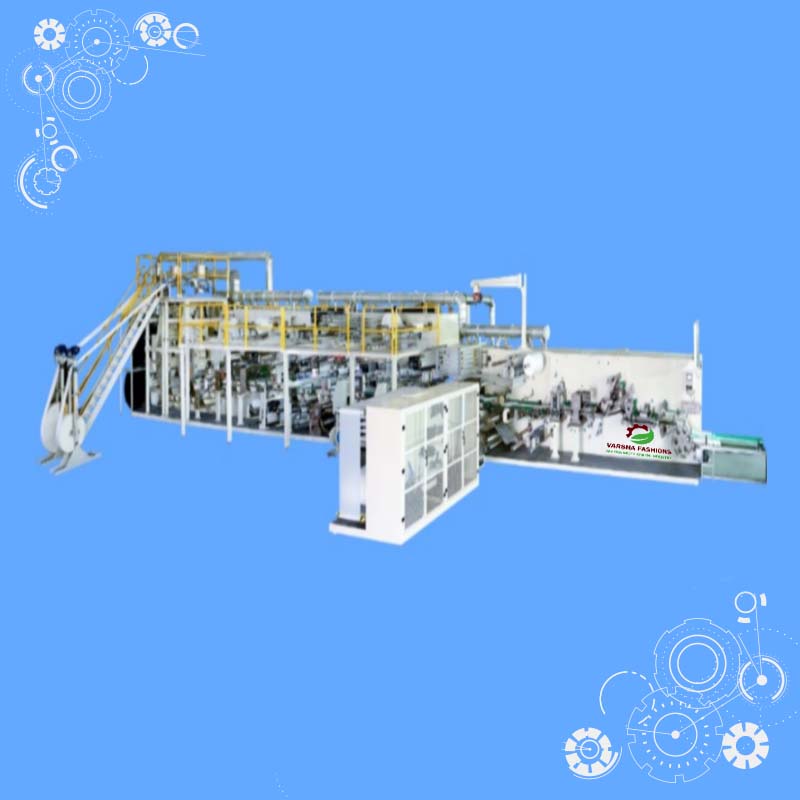

The adult diaper-making machine is specialised equipment used to produce disposable adult diapers. The machine typically includes a range of components, like unwinders, tension controllers, web guides, embossing units, elastic applicators, cutting systems, and stacking devices. It produces high-quality diapers with features like a leak guard, and wetness indicators and has elastic waistbands and stickers. The machines are equipped with advanced technology, including PLC control systems and touchscreen interfaces, to ensure efficient and user-friendly operation. It can also handle various product features, such as size, shape, absorbency, and fastening options. The end result is a high-quality, comfortable, and effective adult diaper that meets the needs of users with incontinence or mobility issues.

Copyright © varshafashion. All Rights Reserved. Website Development & Digital Partner – BUSFAM