Discover our cutting-edge equipment designed to produce high-quality and safe health and hygiene products efficiently.

The VF-700 Baby Diaper Making Machine is a versatile option for producing both baby and adult diapers. The popularity of baby diapers is on the rise due to their convenience, improved hygiene, and reduced risk of skin ailments. Additionally, this machine retains its resale value even after its initial use. Imported from South Korea, Taiwan, and Vietnam, it is constructed using high-quality branded parts and components. Furthermore, its spare parts are readily available in the local market, ensuring easy maintenance and repairs.

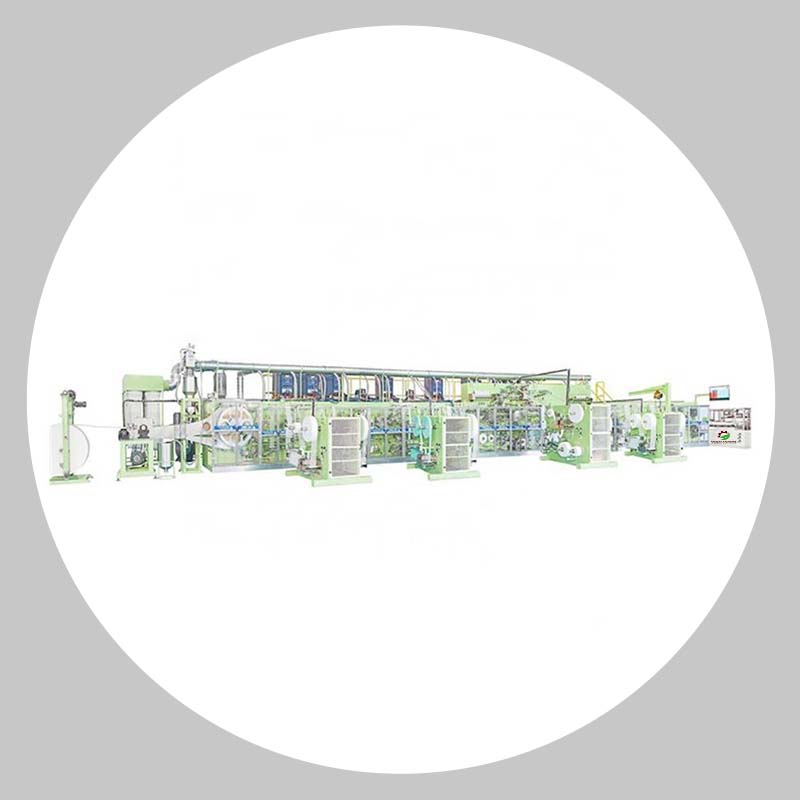

The VF-900 Baby Diaper Making Machine produces diapers for both adults and babies. There has been a steady increase in demand for baby and adult diapers due to the convenience, improved hygiene awareness, and reduced risk of skin diseases that they offer. Since the diapers are made up of super soft and breathable materials, and feature a super absorption surface that effectively absorbs all the liquids and keeps them dry for long hours, people are switching to diapers over clothes.

Notably, this machine has excellent resale value even after its first owner’s production. Manufactured using high-quality branded spares and components, this machine is imported from reputable South Korea, Taiwan, and Vietnam sources. Additionally, its spare parts are readily available in the local market, ensuring uninterrupted and efficient production processes.

The Baby Diaper Making Machine produces both baby and adult diapers, is popular due to convenience, hygiene, and resale value, and uses high-quality parts from South Korea, Taiwan, and Vietnam. Spare parts are easily available locally.

Copyright © varshafashion. All Rights Reserved. Website Development & Digital Partner – BUSFAM