Discover our cutting-edge equipment designed to produce high-quality and safe health and hygiene products efficiently.

There is full modularity in this machine and it can be easily set up. Moreover, full servo motors are used and the machine produces good quality products.

Working Speed: 300 PPM

Power Source: 380V, 50HZ

Air Pressure: 0.6-0.8Mpa

Efficiency: >88%

Pass Rate: >=98%

Capacity: approx. 45 KW

Total Weight: 12 MT

OP Control: HMI Touch

Motors: Full Servo

VF-970 Roll Die Cutting Machine is an automatic machine used in die-cutting, creasing and embossing various PE coated paper, normal paper, corrugating paper and plastic material. These papers can be applied to make paper cup, paper box, medical package, wine package, food package and other environmental friendly products.It adopts micro-computer, HMI, servo positioning, alternating current frequency converter, automatic counting, photoelectric rectifying, pneumatic lock cutting plate, electromagnetic clutch, centralised oil lubrication, overload protection and distinctive gearing. These features help in maintaining the steady pressure, precise positioning, smooth execution, safety measure and reliable operation.

Production Capacity: 180 Times/Min

Max Cutting Area: 940*520 mm

Max Roll Diameter: 1600 mm

Paper Thickness: 120-400gsm

Cutting Precision: 0.20

Max Cutting Pressure: 150 Tons

Machine Weight: 6000 kg

Total Power: 12 KW

Dimensions (L*W*H): 5500*2000*1800 mm

Air Pressure Requirement: 0.5Mpa

Air Pressure Consumption: 0.25m/Min

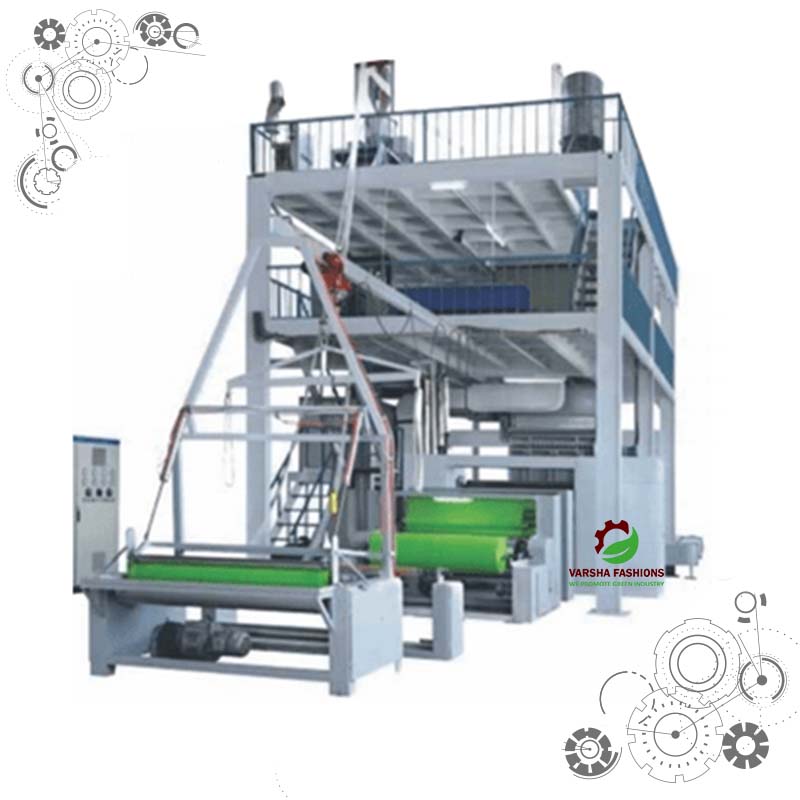

PP Spun-bound Non Woven Fabric Production Line is used for producing non woven fabric. The demand for non-woven fabric has increased since it is an environmentally friendly material compared to plastics. Fabrics produced by this machine is not limited to making Non Woven Bags, but it can also be used in the Healthcare industry e.g – surgical caps, protective clothing etc. This product is available in 3 models – VF-1.6M, VF2.4M, VF-3.2M.

Model: VF-1.6M, VF-2.4M, VF-3.2M

Machine Size: 17mx10mx11m, 17mx11mx11m, 25mx11mx11m

Fabric Thickness: 9-220gsm

Production Capacity: 1800T/Year, 2800T/Year, 3600T/Year

Total Power Capacity: 400kw, 450kw, 1600kw

Running Load: 240kw, 270kw, 900kw

Cycling Water: 50 cubic metre/H, 55 cubic metre/H

Water Supply Ability: 5-10 cubic metre/H, 1-15 cubic metre/H

VF 700 Aluminium Foil Food Container Making Machine is a 4 cavity layer machine. It is composed of an auto-lubricated feeder, length controller, control panel, pneumatic punch, mould, conveyor, scrap collector and scrap presser. It consists of double electromagnetism valves and a pressure relay. Operational safety and reliability of this machine are guaranteed.

Model: VF-700

Production Speed: 120pcs/min

Cavity Type: 4 Cavity

Power Supply: 380 V, 50Hz

Total Power: 15 kw

Space Required: 800 sqft.

Machine Weight: 5000kg

Man-Power Required: 1 skilled / 1 un-skilled

VF 600 Aluminium Foil Food Container Making Machine is a double cavity layer machine. It is composed of an auto-lubricated feeder, length controller, control panel, pneumatic punch, mould, conveyor, scrap collector and scrap presser. It consists of double electromagnetism valves and a pressure relay. Operational safety and reliability of this machine are guaranteed.

Model: VF-600

Production Speed: 65pcs/min

Cavity Type: 2 Cavity

Power Supply: 380 V, 50Hz

Total Power: 15 kw

Space Required: 800 sqft.

Machine Weight: 2500 kg

Man-Power Required: 1 skilled / 1 un-skilled

Varsha Fashions Fly Ash Brick Production Line has an electric cabinet which controls the whole production – from raw material batching to concrete block stacking. This saves labour cost and improves production efficiency. Below is the Theoretical Production Capacity of this machine.

Name | Specification | Block Making Period | Blocks Produced Per Mold (block) | Production Capacity (blocks/hour ) |

Hollow Block | 400’200’200 | 15s-20s | 12 | 2160-2880 |

Block With Multiple Holes | 240’115’90 | 15s-20s | 30 | 5400-7200 |

Solid Brick | 240’115’53 | 15s-20s | 60 | 10800-14400 |

Paver | 200’100’60 | 20s | 42 | 7560 |

I Shape Paver | 200’163’60 | 20s | 28 | 4320 |

Vibration Force: 100-130

Block Making Period (s): 15-20

Vibration Force (kn): 10-130

Vibration Frequency: 2800-4500

Host Machine Power: 56.2kw

Host Machine Weight: 13.5T

Pallet Size: 1400x900x30-35

VF-750 Four Color Flexo Printing machine is suitable for printing packing materials such as PE, PP bag, cellophane and roll paper, etc. Ideal use case will be producing paper packing bag for food, supermarket handbag, vest bag and clothes bag etc.

Here are some of the features listed below:

Model: VF-650

Color Type: 4 Color

Production Speed: 50M/min

Paper Thickness: 60-250 gsm

Maximum Web Width: 850 mm

Maximum Printing Length: 500 mm

Maximum Printing Width: 840mm

Maximum Cutting Speed: < 50 mm/sec

Total Power: 15 kw

Power Supply: 380 V, 50Hz

Machine Weight: 5500kg

Man-Power Required: 1 skilled / 1 un-skilled

VF-650 Two Color Flexo Printing machine can carry out printing on coarse surfaces of non-woven fabrics. Patterned lines of fine colours can be printed. It features high color saturation, strong adhesive force, good smoothness, and high speed.This machine has stable and excellent printing quality. It is suitable for printing HDPE, LDPE, PP, rolling paper, nonwoven fabric, etc.

Here are some of the features listed below:

Model: VF-650

Color Type: 2 Color

Production Speed: 30M/min

Paper Thickness: 60-250 gsm

Maximum Web Width: 850 mm

Maximum Printing Length: 500 mm

Maximum Printing Width: 840mm

Maximum Cutting Speed: < 50 mm/sec

Total Power: 15 kw

Power Supply: 380 V, 50Hz

Machine Weight: 2500 kg

Space Required: 800sqft.

Man-Power Required: 1 skilled / 1 un-skilled

VF 921 Computer Embroidery Machine is a 21 Head high speed flat embroidery machine with 9 needles per head.This machine’s core parts like shuttle and bobbin case are Japan made, heavy body structure and electronic system from Dahao, easy cording from Jiayu & sequin device from Champion. These machine’s embroidery can easily be applied to clothing design, clothing fabric, high-grade wall cloth and other products in the field. The machine is designed effectively to reduce the noise in the production process, hence improving the stability and quality of embroidery.

Model: VF-921

RPM: 1200

Embroidery Type: Flat

Needles Count: 9 per head

Head Count: 21

Workable size: 300-600-1200

VF-915 Computer Embroidery Machine is a 15 Head high speed flat embroidery machine with 9 needles per head.This machine’s core parts like shuttle and bobbin case are Japan made, heavy body structure and electronic system from Dahao, easy cording from Jiayu & sequin device from Champion. These machine’s embroidery can easily be applied to clothing design, clothing fabric, high-grade wall cloth and other products in the field. The machine is designed effectively to reduce the noise in the production process, hence improving the stability and quality of embroidery.

Model: VF-915

RPM: 1000

Embroidery Type: Flat

Needles Count: 9 per head

Head Count: 15

Workable size: 300-600-1200

Copyright © varshafashion. All Rights Reserved. Website Development & Digital Partner – BUSFAM