Discover our cutting-edge equipment designed to produce high-quality and safe health and hygiene products efficiently.

Disposable dental finger wipes machine manufacturing is fully modular and comes with full servo motors. Easily change the settings and format this machine to create some of the best products in medical hygiene.

There is full modularity in the disposable bibs converting machine which produces high-quality products. Moreover, there is high process reliability from these machines and the settings on this machine are easily settable.

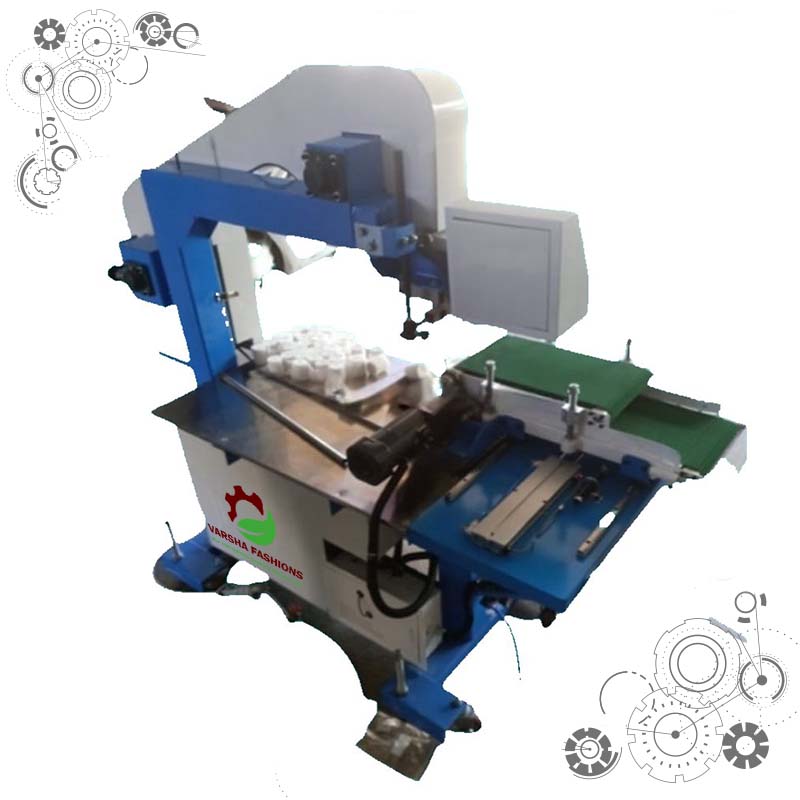

Typically, the production of bandages involves the use of manual or semi-automatic equipment which may lead to poor rolling of the gauze or uneven winding of gauze. Hence, the automatic machine can be used to replace manual operation in the production of bandages at present.

An automatic bandage roll cutting machine is a more hygienic and efficient process of cutting the bandages. The machines offer many benefits and are safe and reliable. Furthermore, this equipment is highly customisable and can seamlessly replace manual production.

Long surgical gown body making machine consists of several parts. They are as follows:

The machine is fully automatic and there is no need for any manual operation. Moreover, only one worker is required to operate the machine. It is the first machine in the industry to realise that the nailing function can be turned on selectively to achieve the dual-use of one machine and two products. Hence, it replaces most of the manual processes.

The Baby Wet Wipes Making Machine has three parts. These are as follows:

Check out the details of the machine parts.

Part 1: Wet Wipes Folding Machine

Product Type | Wet wipes |

Product Speed | 250-380 cuts/min (3000-4500 pcs/min) |

Suitable raw material | air-laid paper, spunlace/ hot rolling non-woven fabric |

Weight of raw material | 40-80 g/m2 |

Folding way | “Z” way pop-up and non-pop up |

Cutting unit |

|

Length of wet tissue | 140-220 mm (setting via touchscreen) |

Size of raw material | (1000-1250) x 𝜙 1000 mm |

Wet tissue unfolded size | (140-220) x (150-250) mm |

Wet tissue folded size | (140-220) x (90-110) mm |

Material supply system | Servo motor |

Cutting System | Converter motor |

Piling System | Servo motor |

Power Supply | 380V 50Hz |

Power | 10 KW |

Size of machine | 10200x 3300 x 2000 mm |

Weight of machine | 5000 kg |

Water Tank | 400 L 2 pcs |

Part 2: Full-auto wet wipes packing machine

Suitable to pack | 40-120pcs/bag |

Product Speed | 30-60 bag/min |

Diameter of raw film roll | <=380mm |

Width of raw film roll | <=420 mm |

Wrapping material | PP,OPP, PET, PE and all suitable films |

Shapes of packing | Pillow type packaging |

Packing length | 100-300mm (touch screen setable) |

Packing width | 80-150 mm (adjustable) |

Height of packing | 10-100 mm (adjustable) |

Horizontal sealing pattern | reciprocation heat sealing |

Drive motor pattern | all servo drive |

Control pattern | Yaskawa MOTION control system |

Operation interface | 7 inch LCD |

Horizontal protection | Torque overload protection |

Air requirements | 0.5-0.8Mpa 0.01m3/min |

Electric power requirements | 380 VAC 50-60Hz |

General power | 7.6 kW |

Dimension of machine | 5410x1150x1900 mm |

Part 3: Full-auto Lid Applicator

Speed | 45-60 pcs/min (eg film length at 250mm) |

Maxi. Packing film length | 300mm (the film length will affect the actual production speed) |

Wet wipes package dimension | (300) * (45-120) * (10-80) mm |

Accuracy | +- 1.2 mm |

Voltage require | 3 phases, AC 380V 50/60 Hz |

Power | 7.5 KW |

Air Pressure | 0.4-0.6 MPa, 1.0 m3 /hr |

Dimension | L 2000 * W 2650 * H 1650 mm |

Weight | 1200 kg |

Surgical masks are very necessary and essential products in hospitals. Hence the disposable surgical mask machine from Varsha Fashions is fully modular and gives very high performance.

VF Surgical Mask Making Machine is used for creating 3-5 layered surgical masks. For any viral infection, a face mask has become one of the most essential weapons to prevent the further spread of the virus. The health industry is so dynamic, pandemic or absence of pandemic would not matter. Masks are essential to this industry. The rising pollution is another reason face masks are not going to go out of the market. And in this crisis, the demand for masks has spiked. These mask machines are imported from South Korea, Taiwan and Vietnam. It is made with high-quality branded spares and components. The spare parts of this machine are always available in the local market.

This machine produces tri-fold fish-shaped masks, whose whole process is automated. The nose-wire welding process, the production of the mask body and the nailing of the ear bands is fully automated. The machine requires no manual operation. The entire machine has an aluminium alloy structure which does not rust. Lastly, there is PLC microcomputer control and high stability. The daily production is 24,000-28,800 pieces.

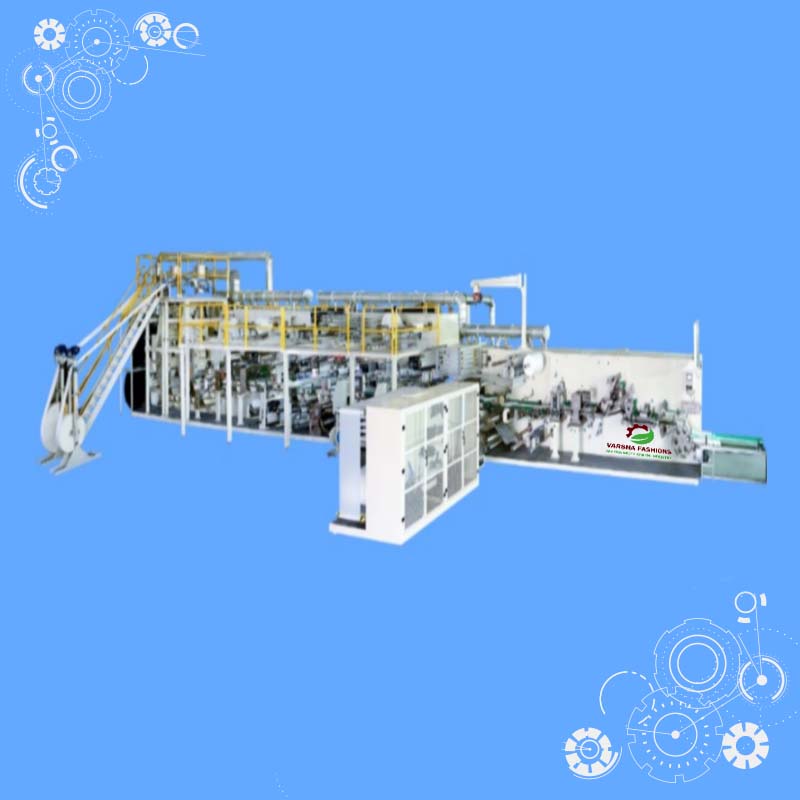

The adult diaper-making machine is specialised equipment used to produce disposable adult diapers. The machine typically includes a range of components, like unwinders, tension controllers, web guides, embossing units, elastic applicators, cutting systems, and stacking devices. It produces high-quality diapers with features like a leak guard, and wetness indicators and has elastic waistbands and stickers. The machines are equipped with advanced technology, including PLC control systems and touchscreen interfaces, to ensure efficient and user-friendly operation. It can also handle various product features, such as size, shape, absorbency, and fastening options. The end result is a high-quality, comfortable, and effective adult diaper that meets the needs of users with incontinence or mobility issues.

Copyright © varshafashion. All Rights Reserved. Website Development & Digital Partner – BUSFAM